|

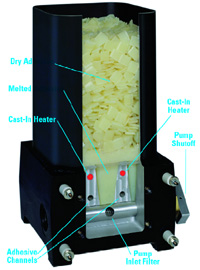

The DYNAMINI hot melt adhesive supply unit with the "HVH" High Volume Hopper is a computer-controlled hot melt glue supply unit Its easy-to-use, all-icon control panel is internationally operator friendly and is available for either 120v or 200-240v service. The DYNAMINI hot melt adhesive supply unit with the "HVH" High Volume Hopper is a computer-controlled hot melt glue supply unit Its easy-to-use, all-icon control panel is internationally operator friendly and is available for either 120v or 200-240v service.

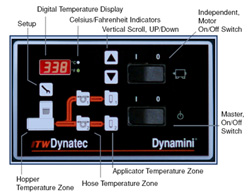

The Dynamini system provides accurate, proportionate temperature control for the hopper, hoses and applicators. Sequential start-up delays may be programmed for turn-on of the hoses and heads.

The temperature control can interlock the parent machine with preselected adhesive temperatures so that production automatically begins when adhesive temperatures are correct for the application. All system temperature values can easily and quickly be programmed.

Digital readout of system conditions is provided. Optional external audible signals or lights which alert the operator to alarm conditions may be wired in. The CPU monitors the electronic circuitry and provides alarms for error conditions.

|

Dynamini Product Literature Downloads:

Fast Brochure Download (PDF)

High Res Brochure Download

Service and Operating Manual English

Service and Operating Manual Spanish

|

Dynamini HVH- The Dynatec Advantage

Dynamini HVH- The Dynatec Advantage

- MELT-ON-DEMAND Hopper Grid extends hot melt glue life and performance

- Self-diagnostic P.I.D. Digital Temperature Controller with platinum sensor accuracy

- 110/120V and 200/240V configurations fitted with either a piston or gear pump

- Easily removable access covers completely expose all components for easy maintenance

DYNAMINI Advantages

- Exceptional value in a small hot melt unit

- Melt-On-Demand hopper grid virtually eliminates adhesive charring

- 7 year melt-on-demand hopper warranty

- Accurate and reliable microprocessor proportionate temperature controller

- Conforms to CE requirements

Control Panel Advantages

Digital set-point and actual temperature indicator takes the guess work out of correct temperature monitoring and control

Digital set-point and actual temperature indicator takes the guess work out of correct temperature monitoring and control- Temperature indicator can be easily converted to Celsius or Fahrenheit readings

- Easy to operate; hopper, hose and applicator zone control icons

- Large scroll UP or scroll DOWN arrows permit the operator to quickly set the various zone temperatures

- Control panel locking limits operator access

- Pump motor on/off switch allows for manual control

- Standby temperature programming lowers the adhesive temperature during inactive periods

- Independent temperature control of the hopper, hoses and applicators to permit the precise metering of adhesive

- Platinum sensor accuracy for exact temperature control